NIKKEN

Super Slow CHANNEL

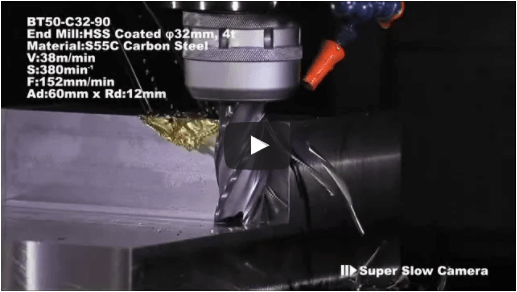

“Chips”generated during metal machining.Since its founding, Nikken has been paying attention to the condition of these chips.

Take a look at the super slow motion video showing the“chips of absolute quality,”

We continue to improve toward achieving a of precision in order to maximize high-accuracy metal machining technology.

Product Video

NC TOOLING SYSTEM

ZERO ZERO HOLDER

High Speed Shrink Fit Device

Milling Chuck

Major Dream Holder

-

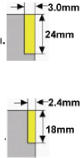

NBT30-MDSK10-50 SK10-10

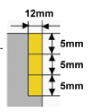

Material:S50C Carbide φ10 4t

Nikken cutting conditions

V165m/min.

s5,300min-1

F2,200mm/min.

88cc/min.

Cutting conditions

recommended

by cutting tool manufacturer

V100m/min.

S3,200min-1

F1,100mm/min.

33cc/min.

-

NBT30-MDQ26-60

Material:S50C φ32

Nikken cutting conditions

V300m/min.

S3,000min-1

f0.06mm/rev.

F180mm/min.

Cutting conditions

recommended

by cutting tool manufacturer

V100m/min.

S1,000min-1

f0.06mm/rev.

F60mm/min.

-

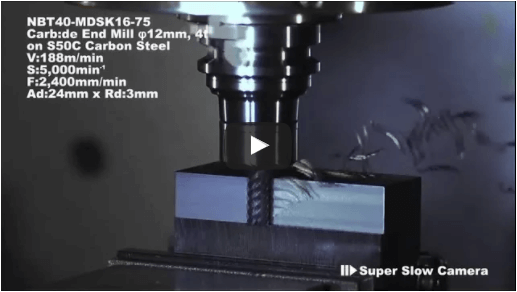

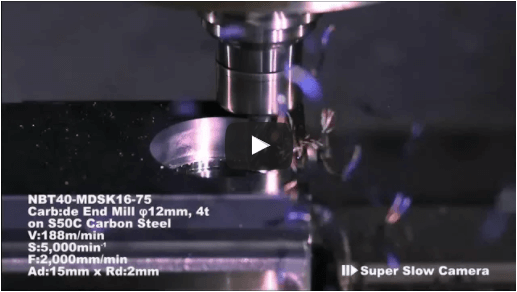

NBT40-MDSK16-75 SK10-10

Material:S50C Carbide φ12 4t

Machining time. 2min. 10sec.

Nikken cutting conditions

V188m/min.

S5,000min-1

F2,400mm/min.

173cc/min.

Cutting conditions

recommended

by cutting tool manufacturer

V100m/min.

S2,650min-1

F1,100mm/min.

48cc/min.

-

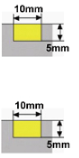

NBT40-MDSK10-75 SK10-10

Material:S50C Carbide φ10 4t

Nikken cutting conditions

V125m/min.

S4,000min-1

F1,000mm/min.

50cc/min.

Cutting conditions

recommended

by cutting tool manufacturer

V80m/min.

S2,550min-1

F610mm/min.

31cc/min.

-

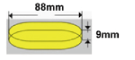

NBT40-MDQ26-65

Material:S50C φ25

Nikken cutting conditions

V300m/min.

S3,800min-1

f0.06mm/rev.

F230mm/min.

Cutting conditions

recommended

by cutting tool manufacturer

V100m/min.

S1,300min-1

f0.06mm/rev.

F80mm/min.

-

NBT40-MDSK10-90

Material:S50C Carbide φ8 w/o hole

jet Coolant Nut Coolant Pressure:

0.5-2.0MPa

Nikken cutting conditions

V125m/min.

S5,000min-1

f0.3mm/rev.

F1,500mm/min.

Cutting conditions

recommended

by cutting tool manufacturer

V100m/min.

S4,000min-1

f0.2mm/rev.

F800mm/min. -

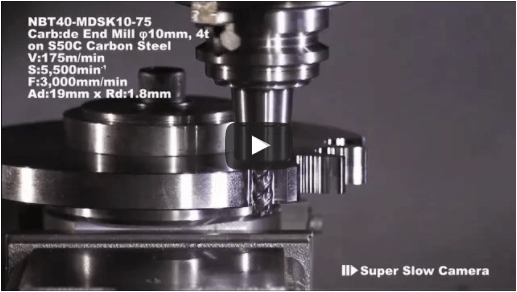

NBT40-MDSK10-75 SK10-10

Material:S50C Carbide φ10 4t

Nikken cutting conditions

V173m/min.

S5,500min-1

F3,000mm/min.

Trochoidal Milling

Machining:25sec.

Cutting conditions

recommended

by cutting tool manufacturer

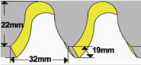

Ad19mm X Rd1.8mm

Major Dream Pro-Endmill

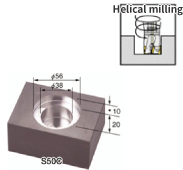

NBT40-MDPE20 Helical milling

Cycle time:40sec

Material:S50C

NBT40-MDPE20 Groove milling

Material:S50C

V=150m/min.

S=2,400min-1

F=0.1mm/teeth

F=720mm/min.

NBT40-MDPE20 Helical milling

Cycle time:35sec

Material:S50C

NBT40-MDPE20 Lateral milling

Material:S50C

V=150m/min.

S=2,400min-1

F=0.12mm/teeth

F=860mm/min.

NBT40-MDPE32 Helical milling

Material:Aluminium

V=900m/min.

S=9,000min-1

f=0.12mm/teeth

F=3,000mm/min.

NBT30-MDPE20-75

Material:SUS304Material:SUS304

HITACHI

ASRM2020R-3,

JX1060

V180m/min.

S2,870min-1

f0.8mm/tooth

F6,888mm/min.

NBT30-MDPE20-75

M10-MDPE20-30Material:S50C

V176m/min.

S2,800min-1

F840mm/min.

50cc/min.

NBT40-MDPE20-90

Material:SUS304

HITACHI

ASRM2020R-3,

JX1060

V180m/min.

S2,870min-1

f1mm/tooth

F8,610mm/min.

ZMAC BORING BAR(Rough boring/Finish boring)

COMBAT Z DRILL

J TYPE SK NUT

BACK SPOT FACING ARBOR

TA CENTER

U-TRONIC

Cutting Demonstration1

Taper boring

Control for contouring the bore

Facing

Back spot facing

Cutting Demonstration2

UT5-500S+AAC unit

CNC Rotary Table

CNC Rotary Table

CNC803TOS

Jig Fixture for Cnc

Rotary Table

Cnc Rotary Table

CNC180 & Robot

High Speed Gear

Cutting Machine

Rotary Table Turbine

Blade CNC321 & CNC321L